BUTTWELD FITTINGS IN PIPING

Buttweld fittings are available in multiple shapes (elbows, tees, reducers, crosses, caps, stub ends), material grades (carbon, high-yield carbon, low-alloy, stainless, duplex, and nickel alloys), and dimensions (2 to 24 inches in seamless execution, and welded for larger pipe sizes).

The key specifications for buttweld fittings are the ASME B16.9 (carbon and alloy fittings) and the MSS SP 43 (that integrates ASME B16.9 for stainless steel, duplex, and nickel alloy BW fittings).

Butt welding fittings have the following benefits

- allow strong, and leak-proof, piping connections

- minimize pressure drops and the turbulence inside the pipeline

- have a long service life

- are rather cheap to purchase and deploy

At Hengtong, we manufacture and stock a lot range of steel piping products . These products include: Steel pipes, Pipe fittings; Forged flanges , in various specifications and materials (Carbon steel ,Alloy steel ,Stainless steel.) We are professional butt weld pipe fittings supplier in China, supply butt weld elbow, butt weld tee, butt weld stub end, butt weld reducer, butt weld cap, butt weld swaged nipple. Any butt weld pipe fittings you need in piping construction, you can find in the list of Hengtong Products !

Elbows Type:

45, 90, 180 Deg. Long/Short Radius Elbows, Equal Tees, Reducing Tees, Equal Crosses, Reducing Crosses, Concentric Reducers, Eccentric Reducers, Caps, Barred Tees, etc.

Pipe Bend:

Size: 3”-48”

Radius: 3D, 4D, 5D, 6D, 8D, 10D

Angels: 22.5Deg, 30Deg, 45Deg, 60Deg, 90Deg

Pipe Fitting Standard:

ANSI B16.9, ANSI B16.28, DIN 2605, DIN2615, DIN2616, JIS B2312, JIS B2313

Pipe Fitting Material:

Carbon Steel

ASTM A 234 WPB, A420 WPL1, WPL3, WPL6,

ASTM A860 WPHY 42, WPHY52, WPHY60, WPHY65, WPHY70

Stainless Steel

ASTM A403 WP304/304L, WP316/316L, WP321, WP347

Alloy Steel

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex & Super Duplex Steel:

ASTM A815 UNS S31803, UNS S32750, UNS S32760

Schedule:STD, XS, XXS, SCH10-SCH160

Pipe Fitting Size:

Carbon Steel: 1/2”-96”

Stainless Steel: 1/2” – 24” (Seamless and ERW), 26” – 72” (Welded)

Features that product hold-

After it being produced by using good quality of alloy, it tends to offer several good features like

Corrosion resistance

Excellent surface finishes

Commendable dimensional accuracy

Anti-corrosive

Withstands easily at the greater temperature and heavy loads

Stress corrosion cracking resistance

APPLICATIONS-

Typical applications include

Food processing equipment.

Kitchen benches, sinks, troughs, equipment and appliance

Chemical containers, including for transport

Heat Exchangers.

Fabrication industries.

Heavy machinery industries..

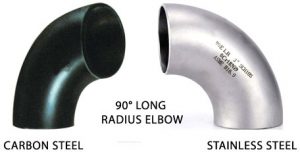

SHORT VS LONG RADIUS ELBOW

The center to face distance of a long radius pipe elbow is always 1.5 times the nominal pipe size, whereas, for a short radius pipe elbow, the center to face distance is equal to the nominal pipe size.

Example:

- For a 4 inches long radius (LR) butt weld elbow, the center to face distance is 4 x 25.4 x 1.5 = 152.4 mm;

- For a short radius butt weld elbow, the center to face distance is instead 4 x 25.4 x 1 = 101.6 mm. Short radius pipe elbows are available only for the 90 and 180-degree configuration (and not for the 45 degrees); instead, long radius elbows are available for all degrees.

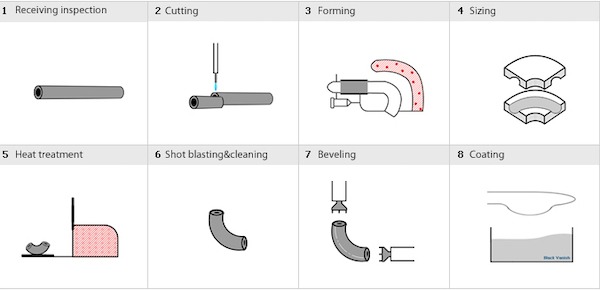

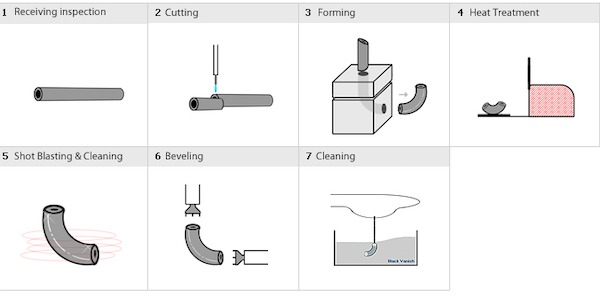

PIPE ELBOW MANUFACTURING PROCESS

Buttweld elbows 45 and 90 degrees can be manufactured in different ways, the main ones are the “mandrel process” and the “cold forming” (other methods are the elliptical forming and the double-seam welding method).

Mandrel Process

Cold forming

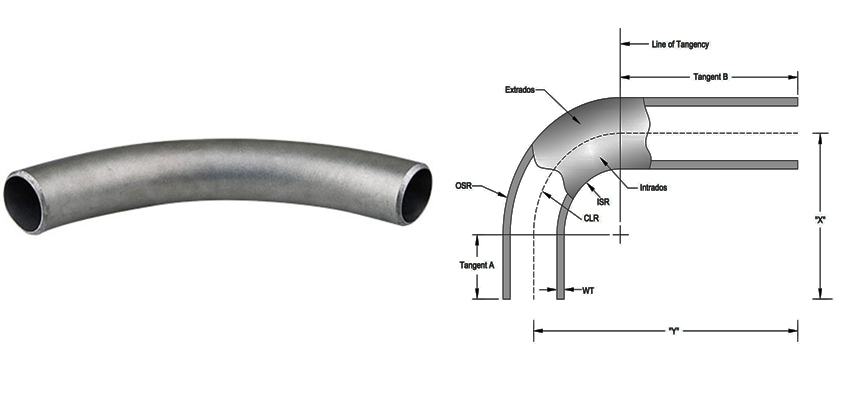

PIPE BENDS

A pipe bend is a generic term to indicate a fittings that changes the direction of the piping system (technically, elbows are pipe bends too but of a standardized type in terms of angle degree and direction). The term “pipe bend” refers to a fitting that offsets the direction of the pipe works, without specifying the actual degree and direction.

Pipe bends are manufacturing by twisting a pipe or a tube using a bending machine, with an hot or a cold forming process. Pipe bends are economical ways of making pipe works layouts decreasing the number of other pipe fittings used.