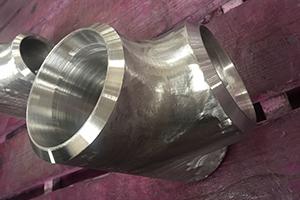

A Tee is a pipe fitting which is shaped like a “T” and has two outlets at 90° to the single inlet connection.

Tees are generally used to combine or split a fluid flow.

Straight Tees have inlets and outlets of the same size.

Pipe tee fittings are used for commercial as well as industrial applications. They are available in several different sizes. They are made from materials including carbon steel, alloy steel, stainless steel. There are different types of pipe tee fittings such as straight tee, female and male branch tee, male and female-run tee, reducing tee and wye tee.

Reducing Tees have inlets and outlets of differing sizes, the smaller one typically being at 90 degrees to the two lager ones.

Equal Tee

Seamless Equal Tees according ASME B16.9 are often used in installations, piping systems or equipment construction. Nijhuis & Wigger can supply suitable Equal Tees for every quality, pipe size and wall thickness.

- Dimensions up to 12”

- Multiple material grades in stock

- Different wall thicknesses available according ASME B 36.10 / 36.19 or specification

- Stock item (see stock programme in downloads)

Reducing Tee

Ansi/Asme B16.9 Butt Weld Tee

Seamless Reducing Tees according ASME B16.9 are often used in installations, piping systems or equipment construction. Nijhuis & Wigger can supply suitable Reducing Tees for every quality, pipe size and wall thickness.

- Dimensions up to 12”

- Multiple material grades in stock

- Different wall thicknesses available according ASME B 36.10 / 36.19 or specification

- Stock item (see stock programme in downloads)

1. Large size stainless steel tee

For production of large size stainless steel tee, two steel plates are placed into corresponding mould for compression molding first by hydraulic press. Then butt welding will be done to attach these two steel pieces together. Through this exact process, the maximum caliber of the seamed stainless steel tee we could produce reaches 100 inches.

-

Tee made by steel plate

-

Large size tee

2. Seamless stainless steel tee

In our company, there are cold press forming machines exclusive for production of seamless tee made of stainless steel. In addition, we can also produce seamless tee with larger size by hot press forming by mould process for customers.

-

Seamless heavy thickness Equal Tee

-

Seamless Equal Tee

3. Forged stainless steel tee

Through forging process, we are also able to manufacture stainless steel socket weld tee or threaded tee.

-

Forged SS Equal Tee

When the size of the branch is same as header pipes, equal tee is used and when the branch size is less than that of header size, reduced tee is used. The three sizes of a tee are End x End x Center. So if you want a tee that is 1’’ on both ends and 3/4’’ in the center it would be 1’’ x 1’’ x 3/4’’.Stainless steel tees, carbon steel tees and special grade tees are widely supplied by us to many industries such as power generation, petrochemical, shipbuilding, paper manufacturing, chemical, pharmaceutical, and fabrication.METLINE also manufactures not so regular buttweld lateral tee in stainless steel, nickel alloys, carbon steel and alloy steel grades.Depending on our customer requirements, we can manufacture and offer straight tees and reducing tees in various grades including 202, 304/304L, 904L, 316/316L, Duplex 2205, Alloy 20, Cupro Nickel, Monel Alloy 400, Inconel Alloy 625, Inconel Alloy 600, Hastelloy Alloy C276, and also in various Aluminium Grades.

Buttweld Pipe Tee Production Range – Equal Tee, Unequal Tee (Reducing Tee)

| Outside Diameter: | Seamless Pipe Tee ( 1/2″~24″), ERW / Welded / Fabricated Pipe Tee (1/2″~48″) |

| Type: | Equal Tees, Reducing Tees |

| Wall Thickness: | 3mm – 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards – Pipe Tee

ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43 DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 EN: EN10253-1, EN10253-2

| ASTM A403 | ASME SA403-Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.25 | Buttwelding Ends ASME B16.28 – Wrought Steel Short Radius Elbows and Buttwelding Returns |

| PMSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

Pipe Tee Material Grades

| Stainless Steel Tee: | ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Carbon Steel Tee: | ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Tee | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Tee: | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex Steel Tee: | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Nickel Alloy Tee: | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

Buttweld Pipe Tee Production Range – Equal Tee, Unequal Tee (Reducing Tee)