Pipe caps fit over or are welded onto the end of a pipe, providing a liquid or gas tight seal.Caps are stocked in Carbon Steel, Alloy steel, and Stainless (304 and 316) Steel.Carbon steel pipe cap is also known as head cap which is used to weld or install on the male thread of end of pipes for blocking the pipelines. It has same function as plug and blind flange.

For Butt Weld Cap

Standard: ASTM A234, MSS SP-75, ASTM A403

Manufacturing Standard: ASME B16.9, DIN2615, JIS B2312

Size Range: 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48”. (DN15-DN1200)

Thickness: SCH 10, SCH 40, SCH 80

Surface Coatings: Black Painted, Varnished, Epoxy Coated, Galvanized

We can produce pipe cap fittings in customized size as per customer required. Usually stock the dimensions in accordance with standards of ASME B16.9, B16.5, B16.11 & BS3799. Our goods are good for waterproof the connections to avoid leakage, and can work high pressure and temperature situation.

ASTM A403 Specificaiton

This specification covers wrought stainles steel fittings for pressure piping applications. They are designed in WP or CR based on ASME or MSS standard dimensions. You need to indicate seamless or welded type while purchasing WP grades fittings.

ASTM A234 Specification

This specifiation covers wrought carbon steel and alloy steel fittings of semaless and welded construction by the standard of ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95 and MSS -SP-97. These fittings are for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures.

Steel Pipe Cap Standard & Material

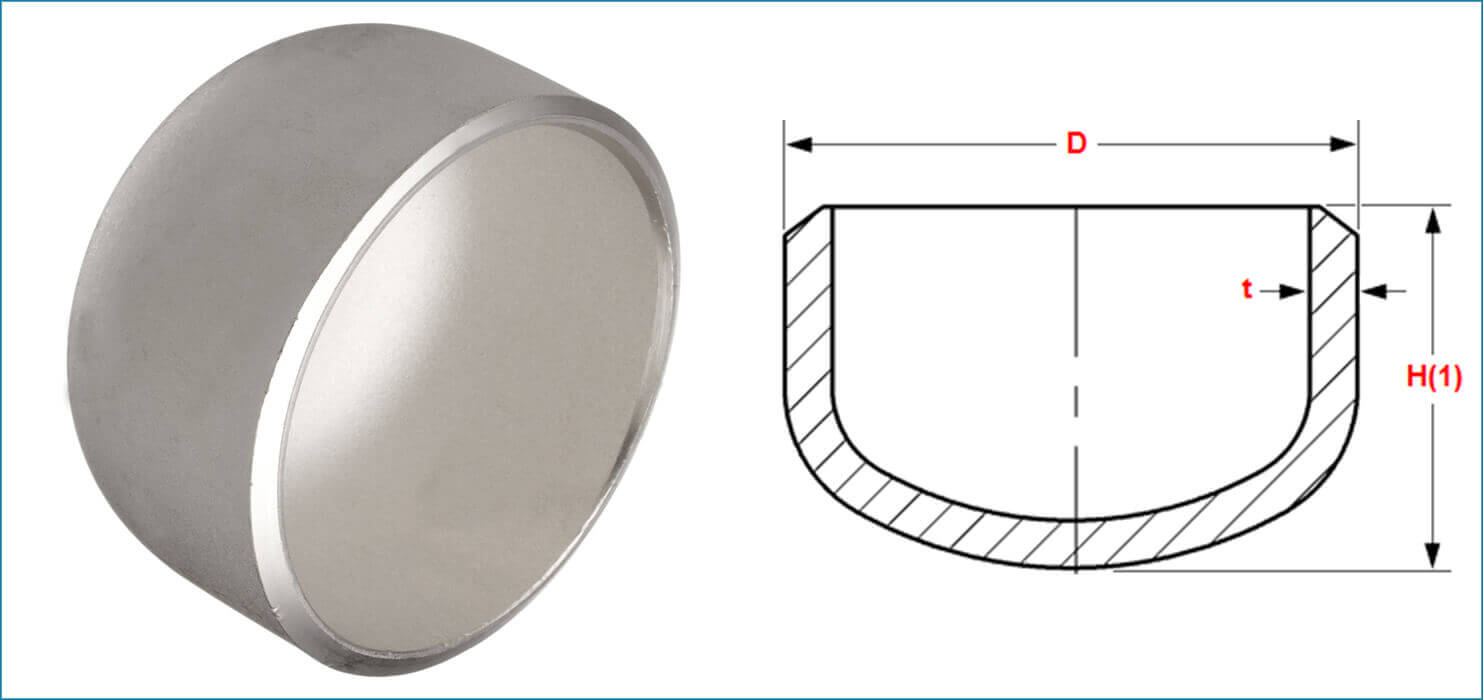

Buttwelding Steel Pipe Cap Dimensions

How to connect pipeline with pipe cap?

Pipe Cap is directly welded to die at the end of the pipeline; at the end of the pipeline can also welding flange, then with a blind flange to death, when necessary can open the blind flange, pipeline check inside. The conventional cap holder with pressure pressing made by thick wall; forging; by spinning large diameter. The need for maintenance or even after the connecting line, with blind, not later, with a pipe cap. With the blind plate has the possibility of leakage, there is a long time, and screw rust died, as useless, the heat pipe is not very easy to heat insulation.

Pipe Cap Applications:

The steel pipe cap is a part of the container. According to the different geometric shapes, it can be divided into spherical, elliptical, dish-shaped, spherical cap, conical shell and flat cover. Among them, spherical, oval, dish, and spherical cap steel caps Also known as convex steel pipe caps. In welding, it is divided into butt welded steel pipe cap and socket welded cap. Used in various container equipment, such as storage tanks, heat exchangers, towers, reactors, boilers and separation equipment.

Pipe End Caps , also known as Pipe Caps, suggest their function through their name: they act as a seal to the end of a pipe. Their primary function is to waterproof piping networks in addition to resisting chemicals, moisture and weather. Our end caps have pressure releasing abilities and flexible. We offer threaded ANSI B16.9 Pipe Caps for quick assembly that also avoid the pipe from getting cracked or damaged. Our End caps are available in high temperature resisting materials, in a variety of colours, finishes and in a wide array of sizes.

Notes:

1) The configuration of the cap is normal ellipse.

2) Length E applies for the thickness not exceeding the Limitting Wall Thickness.For the caps with DN≥650(NPS26), they will be made subject to the sizes agreed between purchaser and manufacturer or be supplied according to manufacturer’s size.

CAPS: Deep Drawing method

One of the most common manufacturing methods for caps, where plate is cut out in a circle and formed by deep drawing.

Deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die.

A drawing press can be used for forming sheet metal into different shapes and the finished shape depends on the final position that the blanks are pushed down in. The metal used in deep drawing must be malleable as well as resistant to stress and tension damage.

How to get high quality pipe cap?

Pipe cap acts as protective device and are designed to protect pipe ends of various shapes. The main purpose of using pipe caps is to waterproof the connections. They are also used to close the the ends of hydraulic or pneumatic pipes and tubes. They are used in the plumbing apparatus of domestic, commercial and industrial water supply lines, machinery and processing equipment etc. They are also fitted on water pump lines with the sole purpose of removing air blocks. Pipe caps are highly demanded as an important category of pipe fittings. If a solvent-weld cap is used to provide for a future connection point, several inches of pipe must be left before the cap; when the cap is cut off for the future connection, enough pipe must remain to allow a new fitting to be glued onto it.

Mark and packing

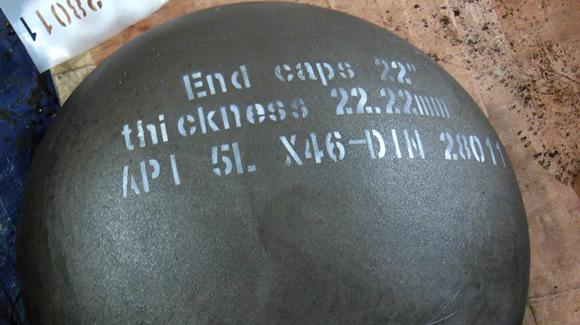

End caps 22″ API 5L X46 – DIN28011