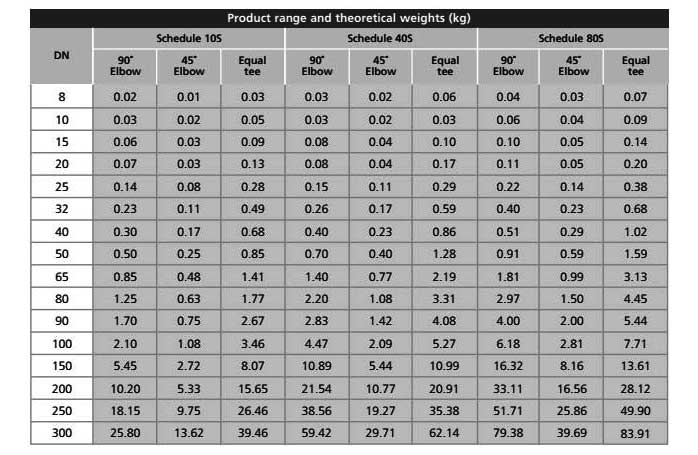

AS A234 WP11 Elbow Weight Chart

Annealed A234 WP11 Cl2 Fittings Specification, Check Attractive Price Offer On Normalized Alloy Steel ASTM A234 WP11 Pipe Fittings In India, Scm420 Chromoly Alloy Steel A234 WP11 Tee Dimensions.

ASTM A234 WP11 Pipe Fittings Specification

| Standard Specification : | ASTM A234 WP11 Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

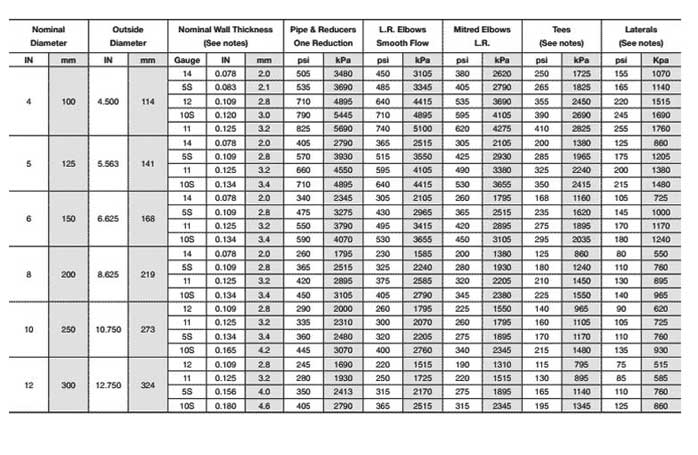

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Standard: | MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, JIS B2312 Fittings |

| Fitting Machining Equipment: | Sand-blasting machine, Press machine, Pushing Machine, electric bevelling machine, Bending machine etc |

| Application: | Fabrication Industry Chemical Industry Water Pipeline Industry Natural Gas Industry Nuclear Power Plant Oil And Gas Industry |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Fitting Faces : | Anti-rust Paint, Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated |

Get Free Quote For SA234 Gr WP11 Fittings, Suppliers Of 4142 Chromoly A234 WP11 Fittings In Mumbai, India, Equivalent Grades Of ASTM A234 WP11 Alloy Steel Welded Pipe Fittings.

A234 WP11 Cl2 Fittings Temperature Range

Contact US Today For Buy ASTM A234 WP11 Alloy Steel Fitting, We provide Multiple Payment Options Of Chromoly A234-WP11 Cl.1 Pipe Elbow, Manufacturers Of ASTM A234 WP11 Fittings In India.

Chemical Composition, Mechanical Properties and Heat Treatment of ASTM A234 WP11

Chemical Composition, Mechanical Properties and Heat Treatment of ASTM A234 WP11

ASTM A234 Standard Specification for Medium and High Temperature Forged and Rolled Carbon and Alloy Steel Pipe Fittings

Steel grade: WP11

chemical composition , %

| Grade | WP11 CL1 | WP11 CL2 | WP11 CL3 |

| C | 0.05-0.15 | 0.05-0.20 | 0.05-0.20 |

| Mn | 0.30-0.60 | 0.30-0.80 | 0.30-0.80 |

| P | 0.030 | 0.040 | 0.040 |

| S | 0.030 | 0.040 | 0.040 |

| And | 0.50-1.00 | 0.50-1.00 | 0.50-1.00 |

| Cr | 1.00-1.50 | 1.00-1.50 | 1.00-1.50 |

| Mo | 0.44-0.65 | 0.44-0.65 | 0.44-0.65 |

* When the pipe fittings are of welded structure, the letter W should be added after the grade number.

tensile properties

| steel grade | WP11 CL1 | WP11 CL2 | WP11 CL3 |

| Tensile strength, min., MPa | 415 | 485 | 520 |

| Yield strength, min., MPa | 205 | 275 | 310 |

Elongation

| Elongation: | portrait | horizontal |

| Minimum values for standard circular specimens or small scale specimens with a gauge length of 4D | twenty two | 14 |

| Rectangular specimens with a wall thickness of 5/16 in. (7.94 mm) and above, and all small-sized specimens tested in full section, with a gauge length of 2 in. (50 mm) | 30 | 20 |

| Rectangular specimens with wall thickness up to 5/16 in. (7.94mm), gauge length 2in. (50mm) (1/2in. wide, 12.7mm) | A | A |

A Allowed from the elongation value listed above, for wall thickness below 5/16in. (7.94mm), for every 1/32in. (0.79mm) thinner, the longitudinal elongation is reduced by 1.5% and the transverse elongation Decrease by 1.0%. The table below gives the minimum values for different wall thicknesses.

| wall thickness | WPB |

| in. | [mm] | portrait | horizontal |

| 5⁄16 (0.312) | 7.94 | 30 | 20 |

| 9⁄32 (0.281) | 7.14 | 28.5 | 19 |

| 1⁄4 (0.250) | 6.35 | 27 | 18 |

| 7⁄32 (0.219) | 5.56 | 25.5 | … |

| 3⁄16 (0.188) | 4.76 | twenty four | … |

| 5⁄32 (0.156) | 3.97 | 22.5 | … |

| 1⁄8 (0.125) | 3.17 | twenty one | … |

| 3⁄32 (0.094) | 2.38 | 19.5 | … |

| 1⁄16 (0.062) | 1.59 | 18 | … |

The table above lists the minimum elongation per 1⁄32 in. [0.79 mm] reduction in wall thickness. When the wall thickness is between the above two values, the value of the minimum elongation is determined by the following formula:

| experimental method | formula |

| portrait | E= 48t + 15.00 |

| horizontal | E = 32t + 10.00 |

E = Elongation at 2 in. or [50 mm] gauge length, %,

t = actual thickness of the specimen, in. [mm].

Hardness: ≤197 HB

heat treatment:

1. WP11 fittings should be delivered at annealed, fully annealed or normalized plus tempered temperature. When normalizing and tempering are adopted, the minimum tempering temperature shall not be lower than 620°C.

ASME B16.11 SA234 Gr WP11 Fittings Chemical Requirements

| WPB B,C,D,E, | WPC C,D,E, | WP11 CL1 | WP11 CL2, | WP11 CL3 |

|---|---|---|---|---|

| Carbon | 0.3 | 0.35 | 0.05–0.15 | 0.05–0.20 |

| Manganese | 0.29–1.06 | 0.29–1.06 | 0.30–0.60 | 0.30–0.80 |

| Phosporus | 0.05 | 0.05 | 0.03 | 0.04 |

| Sulfur | 0.058 | 0.058 | 0.03 | 0.04 |

| Silicon | 0.10 minimum | 0.10 minimum | 0.50–1.00 | 0.50–1.00 |

| Chromium | 0.4 | 0.4 | 1.00–1.50 | 1.00–1.50 |

| Molybdenum | 0.15 max | 0.15 max | 0.44–0.65 | 0.44–0.65 |

| Nickel | 0.4 | 0.4 | … | … |

| Copper | 0.4 | 0.4 | … | … |

| Others | Vanadium 0.08 | Vanadium 0.08 | … | … |

ASTM A234 Grade WP11 Class 2 Butt Weld Fittings Mechanical Requirements

| Tensile Requirements | WPB | WP11CL1 | WP11CL3 |

| Tensile Strength, minimum, ksi[MPa] | 60-85 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [415-585] | [520-690] |

| Yield Strength, minimum, ksi[MPa] | 32 | 30 | 45 |

| [240] | [205] | [310] |