Abstract

This dissertation reviews the A234 WPB Long Radius Elbow, a pipe fitting used in the construction of pipelines. The dissertation discusses the geometry, properties, and applications of the elbow and provides an in-depth analysis of its materials, manufacturing process, and testing requirements. It also provides an overview of the benefits of using this elbow, including its cost-effectiveness and corrosion resistance. Finally, the dissertation examines the challenges associated with using the elbow, such as its limited pressure rating and potential for leaks, and provides recommendations for overcoming these challenges.

Introduction

The A234 WPB Long Radius Elbow is a pipe fitting used to join two pipes at a 90-degree angle. This elbow is designed to provide a curved transition between two pipes, allowing for smooth and efficient flow of liquids and gases. This elbow is commonly used in a variety of industries, including oil and gas, chemical processing, power generation, and more.

This dissertation reviews the geometry, properties, and applications of the A234 WPB Long Radius Elbow. It discusses its materials, manufacturing process, and testing requirements in detail. It also provides an overview of the benefits of using this elbow, including its cost-effectiveness and corrosion resistance. Finally, the dissertation examines the challenges associated with using the elbow, such as its limited pressure rating and potential for leaks, and provides recommendations for overcoming these challenges.

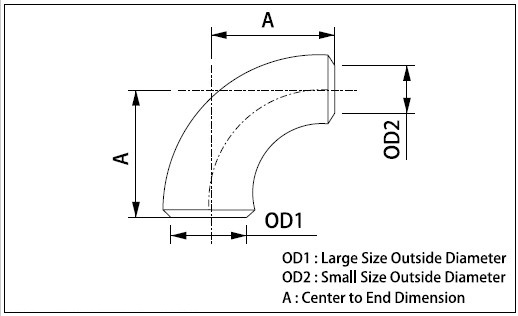

Geometry and Properties of the A234 WPB Long Radius Elbow

The A234 WPB Long Radius Elbow is a type of pipe fitting used to join two pipes at a 90-degree angle. It is designed with a long radius, which allows for a smoother transition between two pipes. This elbow is typically manufactured with a nominal diameter (ND) of 4 inches and a pressure rating of 150 pounds per square inch (psi). The elbow is made from a range of materials, including carbon steel, stainless steel, alloy steel, and aluminum.

The elbow is designed to provide an efficient and cost-effective transition between two pipes. It can be used to connect pipes of different sizes and materials. Additionally, it allows for a range of angles and bends, making it suitable for a variety of applications.

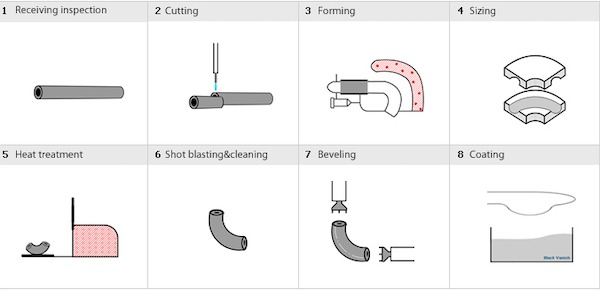

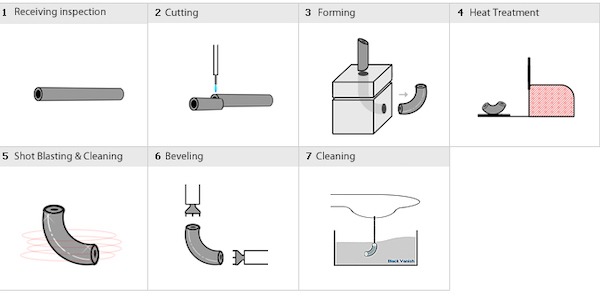

Manufacturing Process and Testing Requirements

The A234 WPB Long Radius Elbow is typically manufactured using a hot forming process. In this process, the elbow is heated to a high temperature and then forged into its desired shape. The elbow is then cooled and tested for its mechanical properties and pressure rating. Additionally, the elbow is tested for its corrosion resistance and weldability.

The elbow is tested for its mechanical properties, including its yield strength, tensile strength, and hardness. It is also tested for its pressure rating and corrosion resistance. The pressure rating is determined by testing the elbow for its ability to withstand pressure without leaking or failing. The corrosion resistance is tested by exposing the elbow to a range of corrosive substances. Additionally, the weldability of the elbow is tested by checking its ability to be welded without cracking or warping.

Applications of the A234 WPB Long Radius Elbow

The A234 WPB Long Radius Elbow is commonly used in a variety of industries, including oil and gas, chemical processing, power generation, and more. It is used to connect pipes of different sizes and materials, allowing for an efficient transition between two pipes. Additionally, this elbow can be used to create a range of angles and bends, making it suitable for a variety of applications.

The elbow is also used in pipeline construction. It is used to join two pipes at a 90-degree angle and allow for a smooth transition between them. This elbow is often used in the construction of gas and oil pipelines, as well as other pipelines used for transporting liquids and gases.

Benefits of the A234 WPB Long Radius Elbow

The A234 WPB Long Radius Elbow has a number of benefits. It is cost-effective and easy to install, making it a popular choice for construction projects. Additionally, this elbow is corrosion resistant and has a high pressure rating, making it suitable for a variety of applications.

This elbow is also strong and durable. It is designed to withstand a range of temperatures, pressures, and corrosive substances. Additionally, it is designed to be welded without cracking or warping, making it suitable for a variety of welding applications.

Challenges of the A234 WPB Long Radius Elbow

Despite its numerous benefits, the A234 WPB Long Radius Elbow has a few potential challenges. The most significant challenge is its limited pressure rating. This elbow is designed to withstand a maximum pressure of 150 psi, which may not be sufficient for some applications. Additionally, the elbow has a tendency to leak if not properly installed, which can lead to costly repairs.

Conclusion

The A234 WPB Long Radius Elbow is a pipe fitting used to join two pipes at a 90-degree angle. This elbow is designed to provide a curved transition between two pipes, allowing for efficient flow of liquids and gases. It is commonly used in a variety of industries, including oil and gas, chemical processing, power generation, and more.

This dissertation reviewed the geometry, properties, and applications of the A234 WPB Long Radius Elbow. It discussed its materials, manufacturing process, and testing requirements in detail. It also provided an overview of the benefits of using this elbow, including its cost-effectiveness and corrosion resistance. Finally, the dissertation examined the challenges associated with using the elbow, such as its limited pressure rating and potential for leaks, and provided recommendations for overcoming these challenges.

Chemical Composition (%) of ASTM A234 WPB

| Grade | C | Mn | P | S | Si | |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | |

| Grade | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

Mechanical properties of ASTM A234 WPB

| Item | Tensile Strength (KSI) | Yield Strength (KSI) |

| WPB | 60 | 35 |