Introduction

Carbon steel butt weld sch 80 45º elbow is one of the most commonly used butt weld fittings in the market. Butt weld fittings are an essential component in any piping system, allowing for the connection of pipes or other components such as valves and pumps. This type of fitting is used in many industrial applications, as well as in water and gas supply systems. In this dissertation, we will discuss the manufacturing process of the carbon steel butt weld sch 80 45° elbow, its design specifications, and the various applications in which it is used.

Manufacturing Process of Carbon Steel Butt Weld Sch 80 45º Elbow

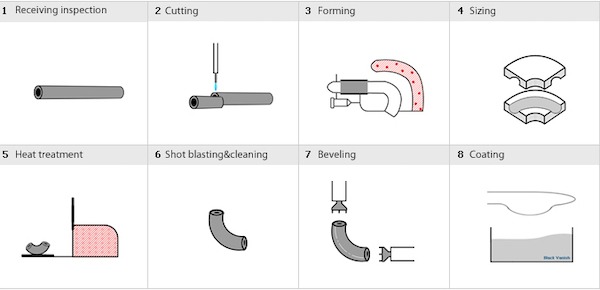

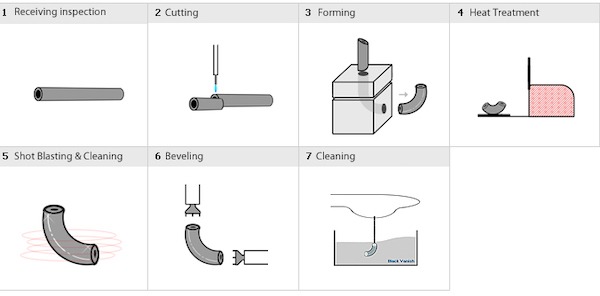

The manufacturing process of a carbon steel butt weld sch 80 45º elbow involves a number of steps. Firstly, the raw material for the fitting is selected. This material is usually carbon steel, as it is strong, durable, and cost-effective. The raw material is then cut to the required length and shape to create the elbow. The cutting process is usually done using a CNC machine, which is computer-controlled and can produce precise shapes and dimensions.

Once the elbow is cut, it is then welded together using a tungsten inert gas (TIG) welding process. The TIG welding process is used in order to create a strong and reliable joint between the two ends of the elbow. The welding process is very precise and can produce high-quality welds that are not only strong but also aesthetically pleasing. Once the welding process is complete, the elbow is then inspected for any defects or imperfections.

Design Specifications of Carbon Steel Butt Weld Sch 80 45º Elbow

The carbon steel butt weld sch 80 45° elbow is a standard fitting that has a specific set of design specifications. These specifications are based on the American Society of Mechanical Engineers (ASME) standards and ensure that the fitting is of a high quality and will function as expected.

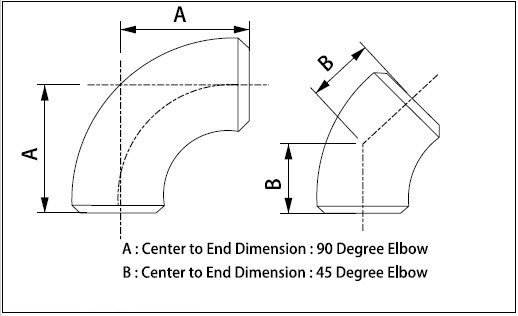

The design specifications of the carbon steel butt weld sch 80 45° elbow include the following:

• Material: Carbon steel

• Angle: 45°

• Size: Sch 80

• Wall Thickness: 1.5mm

• Pressure Rating: 1000psi

• Temperature Rating: -20°C to +200°C

• Threads: ANSI B1.20.1

• Flanges: ASME B16.5

• Welding: TIG welding process

• Testing: Non-destructive testing

Applications of Carbon Steel Butt Weld Sch 80 45º Elbow

The carbon steel butt weld sch 80 45° elbow is a versatile fitting that can be used in many different applications. It is commonly used in industrial applications such as boilers, pressure vessels, and piping systems. It is also used in water and gas supply systems, as well as in the automotive industry.

The carbon steel butt weld sch 80 45° elbow is highly resistant to corrosion and can withstand high temperatures and pressures. This makes it an ideal choice for a variety of applications, such as:

• Heating systems

• Cooling systems

• Power plants

• Oil and gas pipelines

• Chemical plants

• Refineries

• Manufacturing lines

• Automotive industries

Conclusion

The carbon steel butt weld sch 80 45° elbow is a versatile fitting that has a wide range of applications. It is manufactured using high-quality materials and advanced welding techniques, and its design specifications are based on the ASME standards. This type of fitting is highly resistant to corrosion and can withstand high temperatures and pressures. It is used in many industrial and commercial applications, such as heating and cooling systems, power plants, and oil and gas pipelines.