4500 words

Long Radius Elbows and Short Radius Elbows are two types of pipe fittings used for connecting two pipes or tubes of different diameters. They are most commonly used in plumbing, HVAC, and industrial piping systems.

Long Radius Elbows:

Long radius elbows are pipe fittings that have an elbow radius that is 1.5 times the diameter of the pipe. This type of elbow is most commonly used in residential, commercial, and industrial applications where the pipe size is large enough that the elbow has to bend a lot. The long radius elbow is designed to reduce the friction and turbulence that occurs when the pipe is bent. The larger elbow radius also allows for a smoother, more efficient flow of fluid or gas through the system.

Types of reducing elbow : The reducing elbows are available in various types like:

- 90° reducing elbow

- 45° reducing elbow

- 135° reducing elbow

- 180° reducing elbow etc

Short Radius Elbows:

Short radius elbows are pipe fittings that have an elbow radius that is equal to the diameter of the pipe. This type of elbow is most commonly used in tight spaces or areas where the pipe size is small and the elbow needs to bend sharply. The smaller elbow radius creates more friction and turbulence in the system, which can cause pressure losses, but it is necessary to make the bend in tight spaces. The short radius elbow is also used in applications where the pipe has to make a sharp turn, such as going around corners.

Difference between Long Radius Elbows and Short Radius Elbows:

The main difference between long radius elbows and short radius elbows is the elbow radius. Long radius elbows have an elbow radius that is 1.5 times the diameter of the pipe, while short radius elbows have an elbow radius that is equal to the diameter of the pipe. This difference affects the flow of fluid or gas through the system, as well as the amount of pressure loss that occurs.

Long radius elbows are more efficient than short radius elbows, as they reduce the friction and turbulence in the system. This makes them ideal for applications where there is a large pipe size and the elbow has to bend a lot. They are also used in applications where the pipe needs to make a smooth, gradual turn.

Steel elbow material specification

| Material | Steel pipe | Elbow fitting |

| Carbon Steel | A106 Gr A | A234 Gr WPA |

| A106 Gr B | A234 Gr WPB | |

| A106 Gr C | A234 Gr WPC | |

| Carbon steel, alloy, high-temp | A335 Gr P1 | A234 Gr WP1 |

| A335 Gr P11 | A234 Gr WP11 | |

| A335 Gr P12 | A234 Gr WP12 | |

| A335 Gr P22 | A234 Gr WP22 | |

| A335 Gr P5 | A234 Gr WP5 | |

| A335 Gr P9 | A234 Gr WP9 | |

| Carbon steel alloy low-temp | A333 Gr 6 | A420 Gr WPL6 |

| A333 Gr 3 | A420 Gr WPL3 |

ASTM/ ASME A234 WPB / A860 – MSS-SP-75 WPHY 42 / 46 / 52 / 56 / 60 / 65 / 70 Elbow

Low temperature Steel: A420 WPL3 / A420 WPL6 Elbow

Size range: 1/2 to 56 inches (DN 15 to DN 1,400mm), 22.5 Deg, 45 Deg, 90 Deg, 180 Deg

Short radius elbows, on the other hand, are used in tight spaces or areas where the pipe size is small and the elbow needs to bend sharply. They are also used in applications where the pipe has to make a sharp turn, such as going around corners. The smaller elbow radius creates more friction and turbulence in the system, which can cause pressure losses, but it is necessary to make the bend in tight spaces.

In summary, the main difference between long radius elbows and short radius elbows is the elbow radius. Long radius elbows are more efficient and are used in applications where the pipe size is large and the elbow has to bend a lot. Short radius elbows are used in applications where the pipe size is small and the elbow needs to bend sharply.

Types of Elbows based on Length and Radius

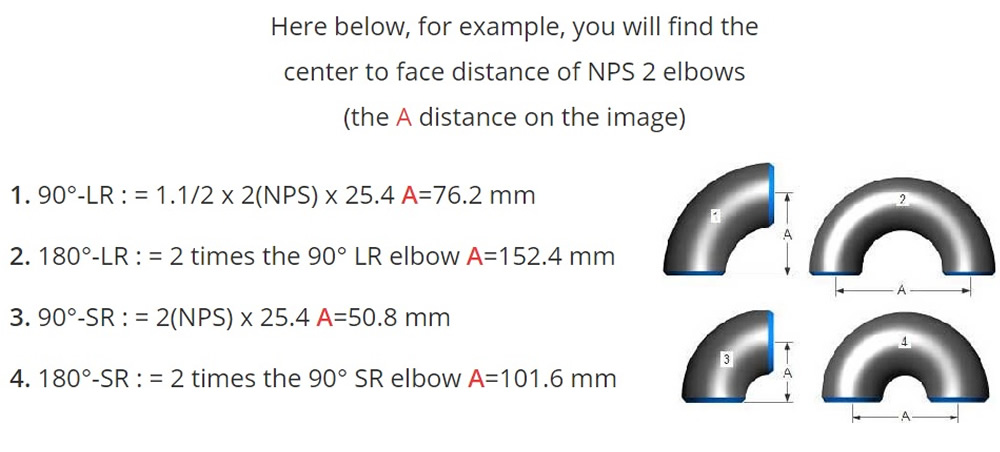

Elbows are split into two groups which define the distance over which the flowing fluid change direction; the center line of one end to the opposite face. This is known as the “Center to Face” distance and is equivalent to the radius through which the elbow is bent.

If the radius is the same as pipe diameter (Center-to-Face dimension of 1.0 X diameter ), it called Short Radius Elbow (SR elbow) used normally for low pressure and low speed pipelines or in tight areas where clearance is the main issue. If the radius is larger than pipe diameter (Center-to-Face dimension of 1.5 X diameter) then we call it a Long Radius Elbow (LR Elbow) used for high pressure and high flow rate pipelines.

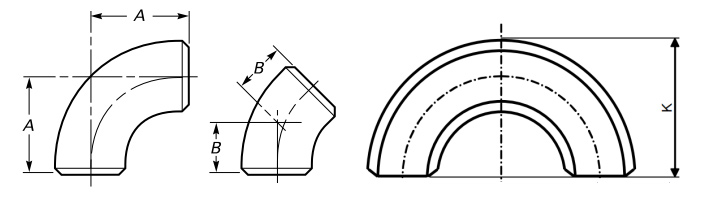

Standard drawing of 90° & 45° long radius (L/R) elbows.

The elbow is used when a pipe changes direction. Elbows can turn up, turn down, turn left, right, or any angle in between. The long radius (L/R) elbows denote elbows with the center-to-end dimension of 1.5D radius which equals to 1.5 x NPS in inch unit. The standard long radius elbows can be further classified as 90° and 45° according to the angle of the flow-direction change.