What is flange standard EN 1092-1?

EN 1092-1 is an European Standard for flanges and their associated pressure/temperature ratings, materials of construction, tolerances and dimensions. It covers a range of flanges up to DN3000 and pressure ratings up to PN400. The standard is widely used for flanges in many industries, including the petrochemical and power generation industries.

What is en 1092-1 equivalent ASME?

EN 1092-1 is equivalent to the American Society of Mechanical Engineers (ASME) B16.5 standard. This standard applies to all flanges, regardless of their size, material, and pressure rating. The two standards are very similar, with the primary difference being that ASME B16.5 includes requirements for weld neck flanges, while EN 1092-1 does not.

What is material EN1092 1 ?

The material used for EN 1092-1 flanges is typically carbon steel, stainless steel, or alloy steel. Carbon steel is the most commonly used material, as it is economical and resistant to corrosion. Stainless steel is often used for applications where corrosion is a concern. Alloy steel is sometimes used for applications that require higher strength and/or temperature resistance.

Flange Facings Dimensions according to Standard EN 1092-1 pdf downloads

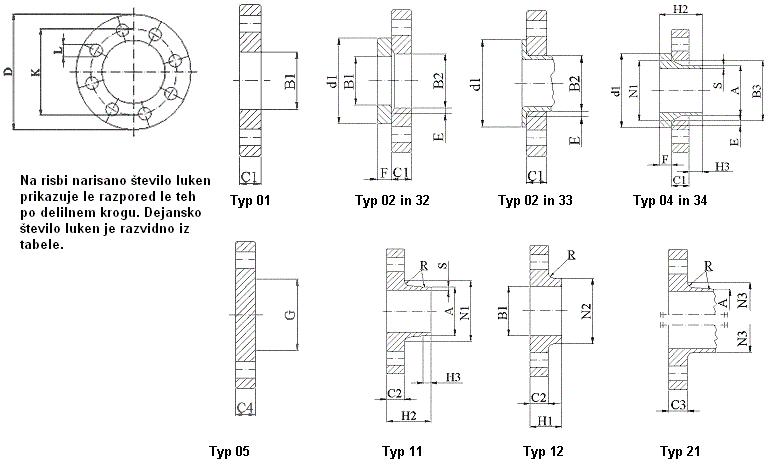

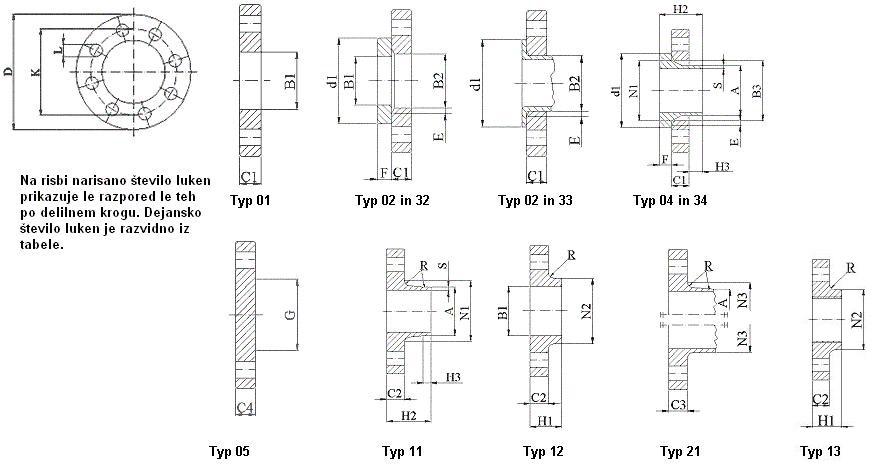

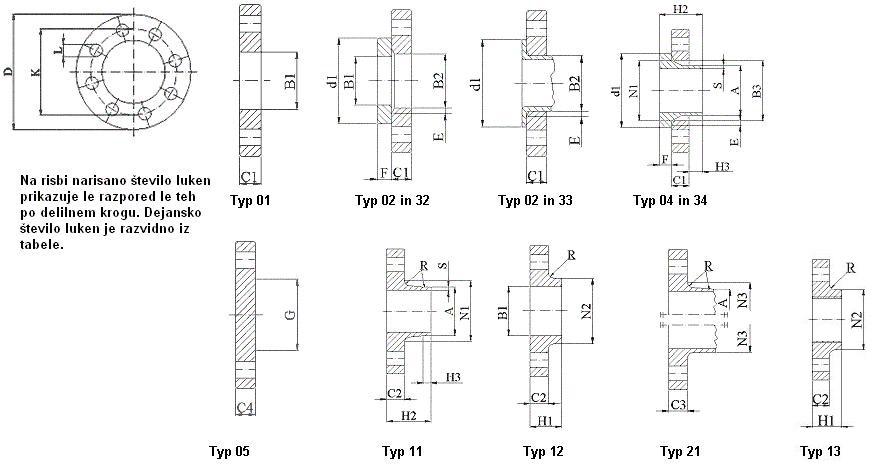

Technical Drawing & General Introduction

Technical Drawing & General Introduction

The drawing of EN 1092-1 Type 01 plate flange with raised face. D: outside diameter; K: diameter of bolt circle; R: diameter of raised face; n: number of bolts; d: diameter of bolt hole; Wt: weight or mass of the Type 01 plate flange; C: thickness of flange; f: height of raised face.

The EN 1092-1 Type 01 flange is also known as “plate flange for welding”. Usually, it is also called “steel ring flange” or “S/O plate flange”. It is a loose type flange which is very similar to slip on flange but without hub. The Type 01 plate flange can slip onto the pipe prior to welding. Two fillet welds, one internal and one external, shall be applied to join the pipe and the flange. They can be furnished with flat face (FF) or raised face (RF) depending on buyer’s requirement. According to EN 1092-1, Type 01 plate flanges are available in 8 pressure ratings: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN40, PN 63 and PN 100. The dimensions and masses for corresponding flanges are listed in tables below. All dimensions are in mm unit and the mass/weight is in kg unit.

EN 1092-1 Type 01 plate flanges may be made from forgings or flat products (plates). They may be machined from rolled or forged bars and forged section steel. For large sizes, they may be bent and electric welded from bars, section steel or strip. The flange may be manufactured from a broad spectrum of material grades covering carbon steel, low alloy steel, stainless steel and other high alloy steels.

EN 1092-1 Type 01 Plate Flanges?

Introduction

ANSI/ASME B16.5 – Pipe Flanges and Flanged Fittings, commonly referred to as ANSI/ASME B16.5, is the most widely used flange standard in the world. It covers steel pipe flanges, forged flanges, and other types of pipe flanges. ANSI/ASME B16.5 includes a variety of flanges, such as slip-on, weld-neck, socket-weld, threaded, and blind flanges.

The ANSI/ASME B16.5 standard has been developed to provide uniformity in the dimensions and pressure ratings of flanges. This standard is widely used by the engineering community, whether in the pipeline industry, power plants, or in the manufacture of industrial equipment.

One of the types of flanges covered by ANSI/ASME B16.5 is the Type 01 Plate flange. These flanges are used for low-pressure applications, such as for pipes carrying water and other liquids. They are usually used in low-pressure systems where the pressure is below 150 psi and up to 300 psi.

What is a Type 01 Plate Flange?

A Type 01 Plate flange is a flat metal disc that is used to connect pipes or other components in a system. It is a flat, circular metal disc with an opening in the center that is used to connect pipes or other components together. The flange is made from a single piece of metal, usually a carbon steel, stainless steel, or alloy steel.

The Type 01 Plate flange is designed to be used with flat-faced pipe. This means that the face of the pipe has a flat surface, which allows the Type 01 Plate flange to be easily and securely welded onto the pipe.

The face of the flange is usually raised slightly from the surface of the pipe. This raised face is used to create a seal between the flange and the pipe. The raised face also helps to prevent leaks and ensures that the pipe and flange are securely connected.

The Type 01 Plate flange is usually used in low-pressure systems, such as for pipes carrying water and other liquids. This is because these flanges are made from a single piece of metal, which makes them less likely to fail under pressure. They are also less expensive than other types of flanges, such as weld-neck flanges.

Dimensions of a Type 01 Plate Flange

The dimensions of a Type 01 Plate flange are determined by the size of the pipe it is being used with. The size of the pipe is usually determined by the nominal pipe size (NPS), which is the inside diameter of the pipe. The size of the flange is then determined by the NPS and the pressure rating of the flange.

The ANSI/ASME B16.5 Type 01 Plate flange is available in sizes ranging from 1/2” to 24”. The pressure rating of the flange is usually determined by the pressure class of the flange, which is usually 150, 300, 400, 600, 900, 1500, and 2500.

The Type 01 Plate flange is usually made from a carbon steel, stainless steel, or alloy steel. The flanges are usually made from either a forged or cast material. The flanges can also be machined to meet specific requirements.

The Type 01 Plate flange is also available in different face types, such as raised face (RF), flat face (FF), and raised face with bevel (RF/BV). Each face type has its own advantages and disadvantages and is designed for a specific application.

The dimensions of the Type 01 Plate flange can be found in the ANSI/ASME B16.5 standard. The standard provides detailed dimensions for each size and pressure class of the Type 01 Plate flange.

Advantages of a Type 01 Plate Flange

The Type 01 Plate flange is an economical and practical solution for low-pressure applications. The flange is made from a single piece of metal, which makes it less likely to fail under pressure. The flange is also less expensive than other types of flanges, such as weld-neck flanges.

The Type 01 Plate flange is also easy to install. It is designed to be used with flat-faced pipe, which allows the flange to be easily and securely welded onto the pipe.

In addition, the Type 01 Plate flange is available in a variety of sizes, pressure classes, and face types, which makes it suitable for a wide range of applications.

Disadvantages of a Type 01 Plate Flange

The Type 01 Plate flange is not suitable for high-pressure applications, as it is not as strong as other types of flanges, such as weld-neck flanges.

The Type 01 Plate flange is also more difficult to inspect and maintain than other types of flanges, as it is made from a single piece of metal.

Conclusion

The ANSI/ASME B16.5 Type 01 Plate flange is a flat, circular metal disc with an opening in the center that is used to connect pipes or other components together. It is designed for low-pressure applications, such as for pipes carrying water and other liquids. The flange is usually made from a single piece of metal, usually a carbon steel, stainless steel, or alloy steel.

The Type 01 Plate flange is an economical and practical solution for low-pressure applications. It is available in a variety of sizes, pressure classes, and face types, which makes it suitable for a wide range of applications. However, it is not suitable for high-pressure applications and is more difficult to inspect and maintain than other types of flanges.

Dimensions of PN 10 Flanges EN 1092-1

NOTE 1: Dimensions N1, N2 and N3 are measured at the intersection of the hub draft angle and the back face of the flange.

NOTE 2: For d1 dimensions see document “Flange facing according to EN 1092-1“.

Dimensions in mm

* For flanges type 21 the outside hub diameter approximately corresponds to the outside pipe diameter,

NOTE: The p/t ratings from EN 1092-1 apply only for flange types 05, 11, 12, 13 and 21 having nominal sizes up to and including DN 600. The p/t rating of all other flanges shall be agreed between the manufacturer and the purchaser.

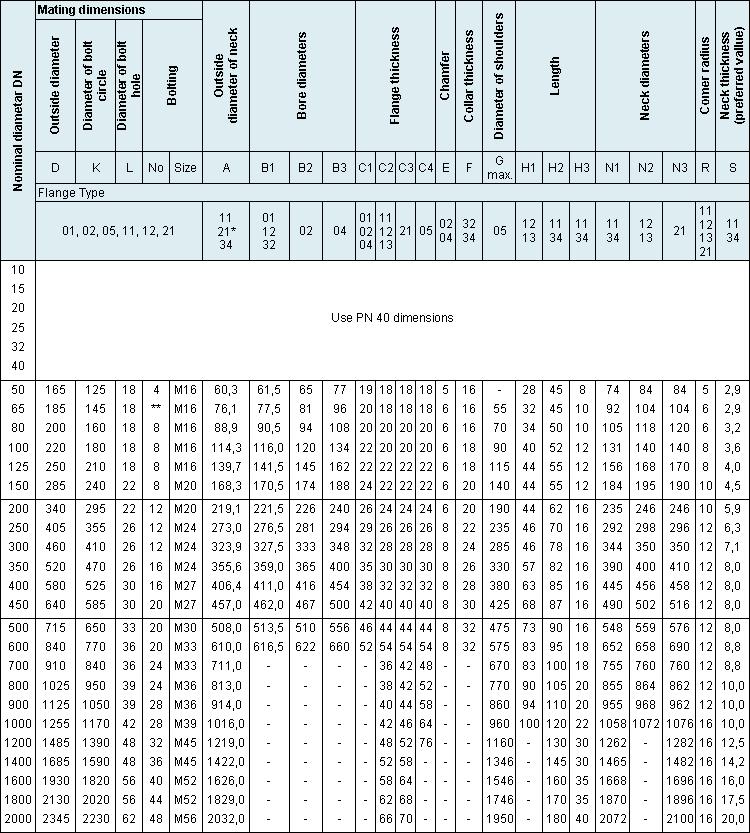

Dimensions of PN 16 Flanges EN 1092-1

NOTE 1: Dimensions N1, N2 and N3 are measured at the intersection of the hub draft angle and the back face of the flange.

NOTE 2: For d1 dimensions see document “Flange facing according to EN 1092-1“.

Dimensions in mm

* For flanges type 21 the outside hub diameter approximately corresponds to the outside pipe diameter,

** 8 holes is preferred however 4 holes may be supplied upon special request by the purchaser.

NOTE: The p/t ratings from EN 1092-1 apply only for flange types 05, 11, 12, 13 and 21 having nominal sizes up to and including DN 600. The p/t rating of all other flanges shall be agreed between the manufacturer and the purchaser.

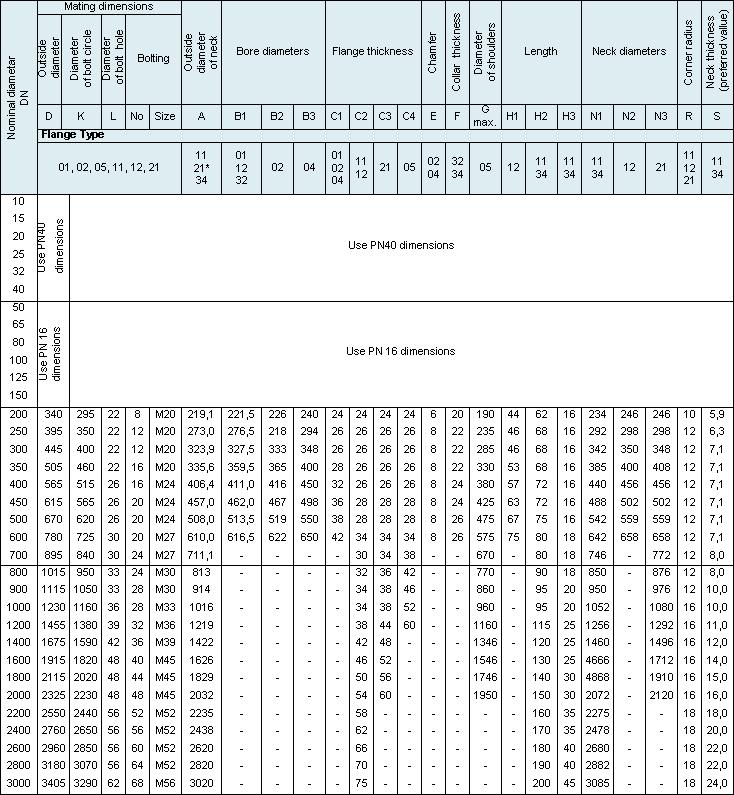

Dimensions of PN 40 Flanges EN 1092-1

NOTE 1: Dimensions N1, N2 and N3 are measured at the intersection of the hub draft angle and the back face of the flange.

NOTE 2: For d1 dimensions see document “Flange facing according to EN 1092-1“.

Dimensions in mm

* For flanges type 21 the outside hub diameter approximately corresponds to the outside pipe diameter,

NOTE: The p/t ratings from EN 1092-1 apply only for flange types 05, 11, 12, 13 and 21 having nominal sizes up to and including DN 600. The p/t rating of all other flanges shall be agreed between the manufacturer and the purchaser.

FLANGES according to EN 1092-1

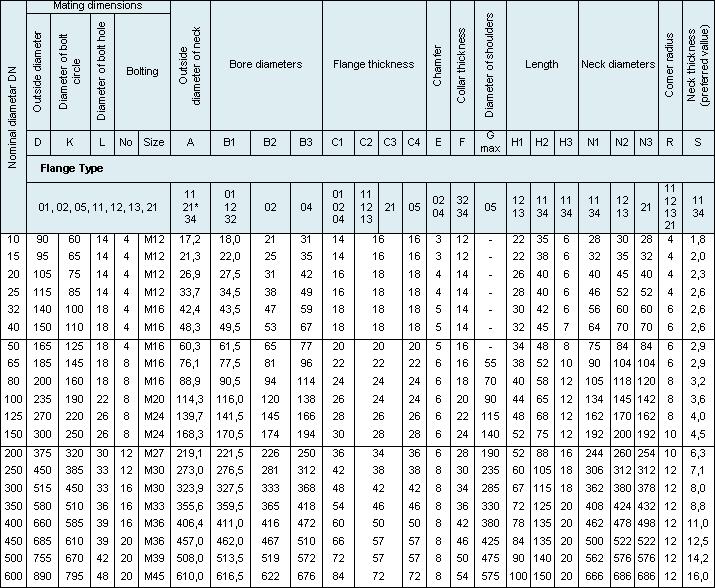

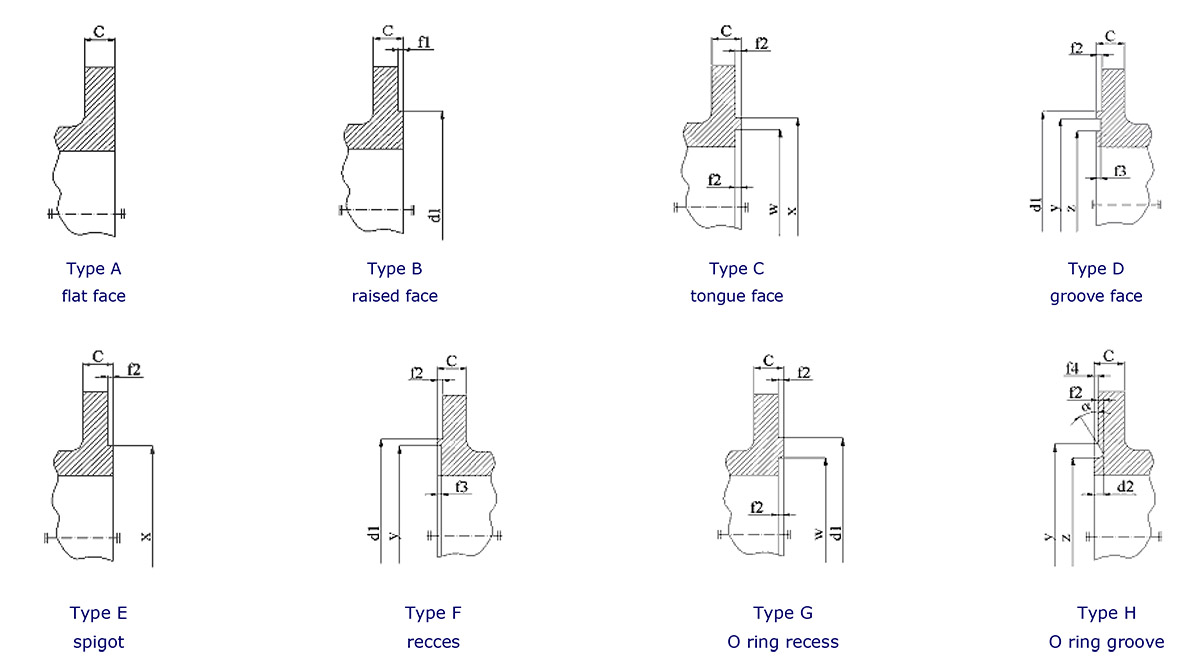

Flange facing dimensions according to EN 1092-1 standard

* For PN 160 flnages form can be only B2, C and D