What is a seamless steel pipe?

Seamless steel pipe is a circular pipe having a hollow section and no seams around it. The seamless steel pipe is made of carbon steel, alloy steel, stainless steel ingot or solid tube blank, and then is made by hot rolling, cold rolling or cold drawing. Seamless pipes are considered superior to welded pipes as they are built using monolithic steel billets, with intrinsic mechanical strength, without seam welds.

Types of seamless steel pipes

Seamless steel pipes include many types of steel pipes, classified according to the use of steel pipes: Boiler Pipe, Fluid Pipe, Line Pipe, Structure Tube, Tubing and Casing Pipe, Low and Medium Pressure Pipe.

what do we have

Hengtong Group is stocked at Industrial Tube & Steel Corporation in both seamless steel pipe with a variety of sizes to meet the structural and mechanical piping requirements for applications in water, petroleum, oil & gas, construction and other industries. Carbon steel pipe can be structural in nature or used in fluid, gas, and oil transmission. We stock carbon steel pipe in ASTM A106, A53, and API 5L specifications. The grade indicates the testing methods required for a given application.

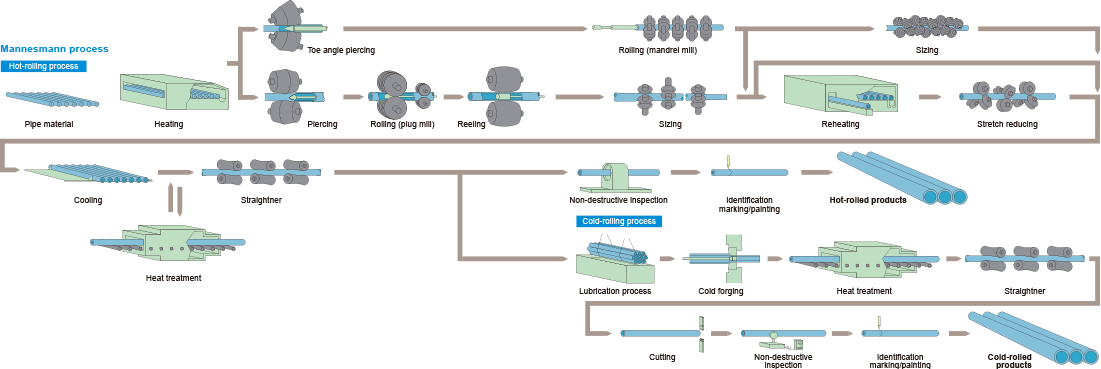

Seamless steel pipe Manufacturing Process

ASTM Standard for seamless steel pipe

| Executive Standard | Grade / Material | Product Name |

| ASTM A53 | A, B | Black and Hot-Dipped Zinc-Coated Steel Pipes Welded and Seamless |

| ASTM A106 | A, B | Seamless Carbon Steel for High Temperature Service |

| ASTM A179 | Low Carbon Steel | Seamless Cold-Drawn Low-Carbon Steel Heat Exchanger and Condenser Tubes |

| ASTM A192 | Low Carbon Steel | Seamless Carbon Steel Boiler Tubes for High Pressure |

| ASTM A210 | A1, C | Seamless Medium-Carbon and Alloy Steel Boiler and Superheater Tubes |

| ASTM A213 | T5, T11, T12, T22

TP 347H |

Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

| ASTM A312 | TP304/304L, TP316/316L | Seamless Steel Pipe for Stainless Materials |

| ASTM A333 | Gr.6 | Seamless and Welded Steel Pipe for Low-Temperature Service |

| ASTM A335 | P9, P11, P22 | Seamless Ferritic Alloy Steel Pipe for High-Temperature Service |

| ASTM A519 | 4130,4140 | Seamless Carbon and Alloy Steel for Mechanical Tubing |

| ASTM A789 | Seamless Ferritic/Austenitic Stainless Steel Tubing for General Service |

API Standard for seamless steel pipe

| Executive Standard | Grade / Material | Product Name |

| API Spec 5CT | J55, K55, N80, L80,C90, C95, T95, P110, M65 | Spectification for Casing and Tubing |

| API Spec 5L PSL1 / PSL2 | A,B X42, X46, X52, X56, X60, X65,. X70 | Specification for Line Pipe |

DIN / EN Standard for seamless steel pipe

| Executive Standard | Grade / Material | Product Name |

| DN 17175/EN10216-2 | ST35, ST45, ST52, 13CrMo44 | Seamless Steel Tube for Elevated Temperature |

| DIN 2391/EN10305-1 | St35, St45, St52 | Cold Drawn Seamless Precision Pipe |

| DIN 1629/EN10216-1 | St37, St45, St52 | Seamless Circular unalloyed Steel Tubes Subject to Special Requirments |

Chemical components & mechanical properties

| Standard | Grade | Chemical Components (%) | Mechanical Properties | ||||||

| ASTM A53 | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | ||

| A | ≤0.25 | – | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | ||

| B | ≤0.30 | – | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 | |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | ||

| ASTM SA179 | A179 | 0.06-0.18 | – | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| ASTM SA192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 | |

| B | 0.28 | – | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | ||

| X42 | 0.28 | – | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | ||

| X46 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | ||

| X52 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | ||

| X56 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | ||

| X60 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | ||

| X65 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | ||

| X70 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | ||

| API 5L PSL2 | B | 0.24 | – | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 | |

| X42 | 0.24 | – | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | ||

| X46 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | ||

| X52 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | ||

| X56 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | ||

| X60 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | ||

| X65 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | ||

| X70 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | ||

| X80 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | ||

Applications of Seamless Hign temperatures and high Pressure Pipe

For applications that feature high temperatures, high pressure, or corrosive materials, seamless steel pipe is often a great solution. Seamless steel pipe can be used in a variety of applications, include:

Heat exchanger

Chemical and petrochemical industry

Power generation and environmental technologies

Ship making/ shipbuilding

Oil and gas applications

Pressure applications

High Temperature Carbon Steel Pipe

ASTM A179, A192, A210 specification covers Carbon Steel Seamless tube for high-temperature service. These pipe are used heat exchangers, condensers, High Temperature Material should furnish to Specification A 530.

ASTM A179 / A179M – 90a Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes

ASTM A192 / A192M Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service

ASTM A210/ASME SA210 Standard Specification for Seamless Medium-Carbon Steel Boiler and Superheater Tubes.

High Temperature Alloy Steel Pipe

ASTM A213, A209 specification covers Alloy Steel Seamless tube for high temperature service. These tube are suitable for bending and similar forming operations, and for fusion welding at high temperatures. High Temperature Alloy Steel tube are also considered as low Alloy Chrome Moly grades.

ASTM/ASME A/SA213 Gr. T2, T5, T5b, T5c, T11, T12, T17, T21, T22, T9, T91

ASTM/ASME A/SA335 Gr. P1, P2, P5, P11, P12, P22

EN10216-2 Gr. 10CrMo9-10,13CrMo4-5,EN10216-2,P195GH,P235GH,P265GH

Seamless Carbon Steel High-Temperature Pipe ( ASTM A106 / ASME SA106 )

A106 like A333 and API 5L, it reverts to ASME B36.10 for the nominal pipe dimensions. Therefore, A106 pipe products are often multi-certified to similar ASTM A53, A333 and API 5L grades, where the requirements of all these specifications are met.

Note that for welding SA106 products, ASME BPVC Section IX considers SA106 GrB to be in the P1G1 alloy grouping (along with SA53 GrB, SA333 Gr6), while SA106 GrC is in the P1G2 alloy grouping.

Alloy steel pipes

ASTM/ ASME : American Society for Testing and Materials(ASTM), American Society of Mechanical Engineers (ASME)

| Description | Standard | Dimension (mm) |

Steel code/ Steel grade |

|---|---|---|---|

| Carbon and alloy steel mechanical tubing, either hot-finished or cold-finished | ASTM A519 | 20-180 x 2-30 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-exchanger Tubes | ASTM A213 09 | 10.3-426 x 1.0-36 | T5, T5b, T9 , T11, T22 ,T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | 1/4″-42″ x SCH20-XXS | Grade1 Gr. 3,Gr..6, Gr.8 , Gr. 9 |

| Seamless ferritic alloy-steel pipe for high-temperature service | ASTM 335/335M | 1/4″-42″ x SCH20-XXS | P5, P9 ,P11, P91, P22, P92 |

DIN/EN- European Standards for steel : Germany Safety(GS), Deutsches Institut für Normung(DIN)

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

|---|---|---|---|

| Seamless Steel Tubes for Elevated Temperature | DIN 17175 | 10-762 x 1.0-120 | St35.8,St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Seamless steel tubes for pressure purposes | EN10216 | 4.0-60.0 x 0.5-8 5-7 m manufacturing lenght |

P235GH TC1, P235GH TC2, 16Mo3 |

| Seamless precision steel tube applications | EN 10305-1 | 13.5-165.1 x 1.8-4.85 | St33.2 |

| Seamless Precision Steel Tube | DIN 2391 | 4.0-60.0 x 0.5-8 | St35, St45, St52 |

JIS : Japanese Industrial Standards (JIS) specifies the standards used for industrial activities in Japan.

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

| Carbon steel/Alloy steel boiler and heat exchanger tubes | JIS G3461,2 | 19.05-114.3 x 2.0-14 | G3461(STB340, STB410, STB510) G3462(STBA22, STBA23) |

| Heat resistant alloy steel pipes that are used for high temperature conveying fluid pipes for heaters and boiler tubes. | JIS G3458 | 10.5-660.4 mm | STPA 12, STPA 20, STPA 22, STPA 23, STPA 24, STPA 25, STPA 26 |