What is Carbon Steel Welded Steel Pipe?

What is Carbon Steel ERW Pipe?

What is Carbon Steel DSAW Pipe?

What is The LSAW Pipe?

What is the SSAW Steel Pipe?

What is Carbon Steel Welded Steel Pipe?

With the ever-evolving industrial applications, Welede piping systems and products have become widely used in numerous construction sectors. Manufacturers have doubled their production rate over the past decade to keep up with the market demands.

Pipe molding can only follow two specific techniques that result in either seamless steel or welded pipe. There is a thin line between seamless steel and welded pipes.

Welded steel pipes are always available in plenty because of their lower production cost and raw materials availability. It is, therefore, one of the most widely used metals in the world. Its application in different industries and the manufacture of numerous products. Welded steel pipe Examples of ASTM or API 5L welded steel pipes include ERW steel pipe,HFW Pipe,LSAW pipe and SSAW pipe.welede carbon steel pipe with a seam on the surface of a steel strip or steel plate that is bent and deformed into a circular shape or a square shape. Steel pipe is a kind of hollow long steel, which is used as a conduit for conveying fluids, such as oil, natural gas, water, gas, steam, etc.

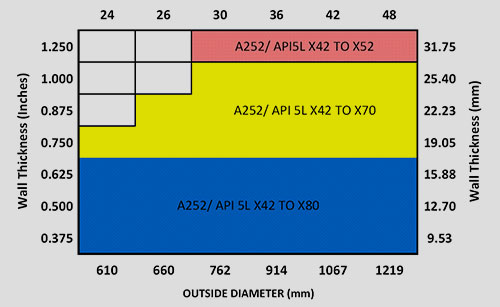

HENGTONG GROUP has an annual manufacturing capacity of more than 326,000 tons. The facility manufactures a broad variety of steel pipe ranging from structural pipe to the highest grades (such as API X80) and has the ability to produce pipe of wall thicknesses ranging from ¼” to 1″ thick and pipe diameters from 24″ to 48″ the pipe .

What is Carbon Steel ERW Pipe?

Electric Resistance Weld (ERW) Carbon Steel Pipe is manufactured by cold forming carbon steel into pipe. The pipe is formed by rolling carbon steel plate and then welding the seam with an electric current.

Many people confuse the ERW pipe with seamless steel because it does not use fusion metals, the weld seam is not always visible, and you cannot feel it.

Applications

Welded steel pipes, as opposed to seamless steel pipes, are widely used in several industries because they are cost-effective. They can also be manufactured in different lengths and welded from different tubing shapes. Application is entirely dependent on the use and other related factors.

Hengtong group supplies a complete inventory of welded carbon steel pipe including ERW steel pipes and DSAW STEEL PIPES, ranging in size from 1/8 inch to 60 inch OD.

| Standard | for erw pipe | ASTM A53 B, ASTM A178, ASTM A252 GR.2 API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 ASTM A500, ASTM A513 EN: S275, S275JR, S355JRH, S355J2H,EN10219-1 ,EN10217-1 S235JR,S275JR,S355,S355JR,S355J2H JIS G3466 |

| for efw pipe | carbon steel efw pipe: ASTM A671,ASTM A672

alloy steel efw pipe: ASTM A691 |

|

| Sizes | Out diameter | 1/2″ -24″ (21.3mm-610mm) |

| Wall Thickness | 1.65mm-20mm |

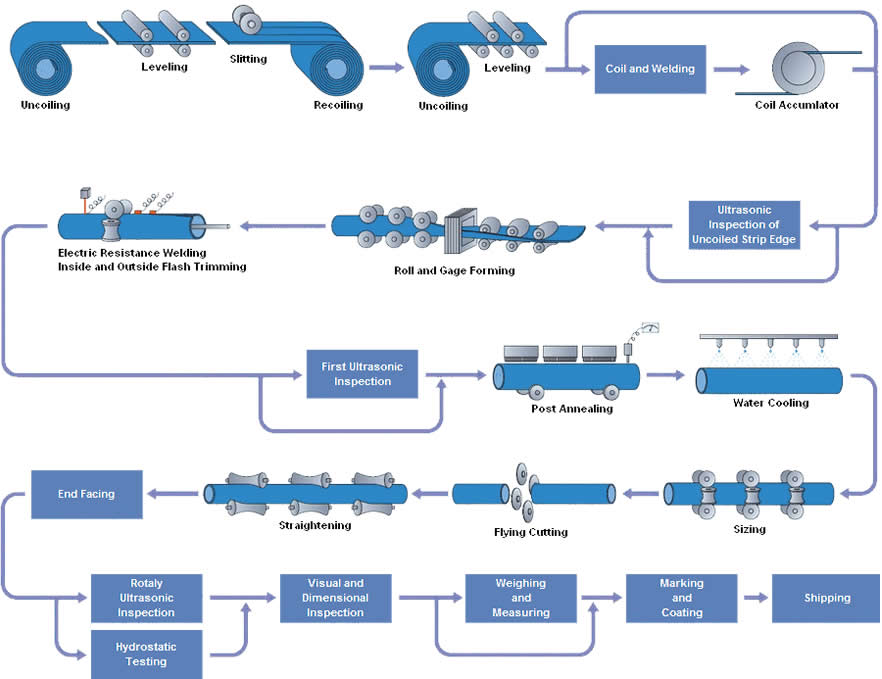

TYPICAL ERW PIPE MANUFACTURING PROCESS

Our manufacturing process generally involves the following stages in a step by step procedure.

What is Carbon Steel DSAW Pipe?

(DSAW) Double Submerged Arc Welded- is available in straight and spiral welded formats and used in a variety of applications: Oil , Gas and Water Transmission,Structural Applications.

Double Submerged Arc Weld (DSAW) Carbon Steel Pipe is manufactured by forming steel plates into cylindrical shapes. This method is typically used for larger diameter pipes, and the main difference between ERW and DSAW is the longitudinal weld.

Manufacturing process of DSAW pipe : Double Submerged Arc Welded (DSAW) is manufactured by first forming steel plates into cylindrical shapes. The edges of the rolled plate are formed to produce v-shaped grooves on the interior and exterior surfaces at the seam. The pipe seam is then welded by an arc welder in a single pass on the interior and exterior surfaces. The welding arc is then submerged under a flux.

Advantages of DSAW pipes:

Straight or spiral welded formats

Very large diameters

Exact inside and/or outside dimensions

DSAW Pipe is distinguishable by the spiral DSAW seam that runs the length of the pipe up to 155 feet.

Products

- GradesAPI-5L GRB, X42, X46, X52, X56, X60, X65, X70, X80, A252-2, A252-3

- DIA Range24″ to 60″ OD

- Wall Thickness.375″ min and .75″ max for 24″ and 26″ dia pipes .375″ min and 1.25″ max for dia greater than 26″

- LengthDouble Random Lengths with min. 38 feet and max. 40.8 feet

Manufacturing process of DSAW steel pipe

What is The LSAW Pipe?

LSAW PIPE (LONGITUDINAL SUBMERGED ARC WELDING),The LSAW pipe diameter range is normally from 16 inch to 60 inch (406mm to 1500mm). They have good performances on high pressure resistance, and low-temperature corrosion resistance.Hengtong group however can supply pipes between 1 inch to 167 inch (21mm up to 4267mm) in diameter and thicknesses between 3/32 inch to 4 inch (2.1mm up to 100mm). Largest diameters and thickness of ESC Steel Pipes are manufactured using LSAW which are highly recommended for load bearing piles, combination wall piles and other applications. In the oil and gas industry, large-diameter API 5L LSAW pipes are use d to transport hydrocarbons over long distances efficiently.

An LSAW pipe (“submerged arc welding”) is manufactured by cutting, bending and welding steel plates (JCOE process).

LSAW pipes compete with seamless and ERW pipes in the size range between 16 and 24 inches but are “must-go” option for pipelines above 24 inches (as 24 inches is the maximum size for commercial seamless pipes).

The two main types of LSAW pipes are the longitudinal (with a single or double straight seam weld, DSAW) and the spiral type (called, HSAW, SSAW or SAWL pipe). Therefore, the difference between DSAW vs. LSAW is that DSAW pipes have a seam weld in the inside and outside of the pipe, whereas LSAW pipes have a single seam weld on the outer surface.

The difference between LSAW and ERW pipes is that LSAW pipes are produced using steel plates, ERW pipes are manufactured starting from steel coils.

In the oil and gas industry, large-diameter API 5L LSAW pipes are used to transport hydrocarbons over long distances efficiently.

HSAW/SSAW spiral weld pipes are used for non-critical applications, as water transmission and distribution (not for oil & gas).

UOE SAWL PIPES

Outside Diameter:Φ508mm- 1118mm (20″- 44″)

Wall Thickness: 6.0-25.4mm 1/4″-1″

Quality Standards: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length: 9-12.3m (30′- 40′)

Standard

API 5L PSL1, API 5L PSL2,ASTM A53/A252

Material

GR.B,X42,X46,X52,X56,X60,X65,X70,GR1,GR2,GR3

JCOE SAWL PIPES

Outside Diameter:Φ406mm- 1626mm (16″ – 64″ )

Wall Thickness:6.0- 75mm (1/4″ – 3″ )

Quality Standards:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length:3-12.5m ( 10′- 41′ )

Standard

API 5L PSL1, API 5L PSL2,ASTM A53/A252

Material

GR.B,X42,X46,X52,X56,X60,X65,X70,GR1,GR2,GR3

Tolerance of Outside Diameter and Wall Thickness

| Types | Standard | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| PIPE end OD deviation | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

| Wall thickness | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm<t<15.0mm, ±0.11<=”” p=””></t<15.0mm,> |

| D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Chemical Composition and Mechanical Properties of LSAW Steel Pipe

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Mn | Si | S | P | Yield Strength

(Mpa) |

Tensile Strength

(Mpa) |

||

| DIN 17100 | ST37-2 | 0.2 | – | – | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | – | – | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | – | – | – | 0.050 | 0.050 | 235 | 400 |

| SS490 | – | – | – | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | – | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | – | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | – | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | – | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | – | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | – | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | – | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | – | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | – | 0.03 | 0.03 | 585 | 570 | |

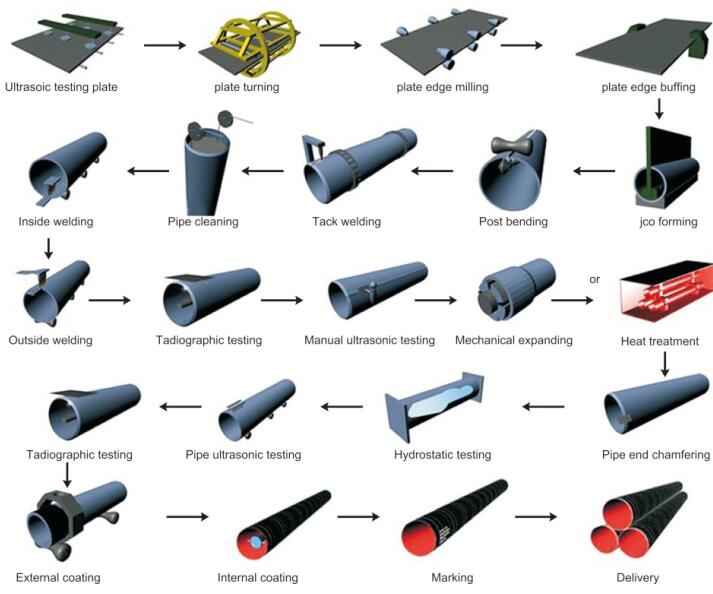

LSAW PIPE MANUFACTURING PROCESS

LSAW pipes are manufactured with the so-called JCOE process, starting from steel plates as illustrated below.

UOE LSAW pipe forming process:

The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.

JCOE LSAW pipe forming process:

Forming: After several steps of stamping on the JCO forming machine, first half of the steel plate is pressed into a “J” shape, then the other half of the steel plate is pressed into a “J” to form a “C” shape, and finally pressurized from the middle to form An open “O”-shaped tube blank is formed.

Anti-Corrosion for reinforcing steel and elbow coating

What is the SSAW Steel Pipe?

SSAW pipe full name is Spiral Submerged arc welding pipe. The pipe is formed by spiral submerged arc welding technology which is called SSAW pipe. Generally speaking, when it comes to the same standard and steel grade, the price of SSAW pipe is cheaper or lower than ERW pipe and LSAW pipe. The strength is higher than the straight seam welded pipe.

Spiral steel pipes (SSAW Pipe) and straight seam steel pipes are currently widely used in water pipelines, construction and other industries, but there is a big difference between the two.

1. Different pressure-bearing capacity

The strength of spiral steel pipes is generally higher than that of straight seam steel pipes. The main production process is submerged arc welding. Spiral steel pipes can use blanks of the same width to produce steel pipes with different pipe diameters, and can also use narrower blanks to produce steel pipes with larger pipe diameters.

2. Different specifications

The specifications of spiral steel pipes are generally above 219mm, and most of them are of large diameter. The specifications of straight seam steel pipes are mostly of small diameter, but some manufacturers also have many large diameters.

3. Different prices

Spiral steel pipes are mostly settled by measuring rulers, and the price of straight seam steel pipes is mostly settled by weighing, but the price of spiral steel pipe is about 300 yuan/ton cheaper than that of straight seam steel pipe.

Traditional SSAW pipes were historically limited to low pressure applications. However, modern SSAW pipes have been used extensively in Russia, Canada, and Asian countries in high pressure gas pipelines.

SSAW PIPE Steel Grade:

ASTM A588/A588M

ASTM A252 GR 1, GR 2, GR 3

ASTM A572: GR 42, GR 50, GR 55, GR 55, GR 60, GR65

API 5L: GR B, X42, X46, X52, X56, X60, X65, X70, X80

EN: S235JR, S275JR, S355JR, S355JOH, S420, S450, S460

Outer Diameter: 219.1mm – 4064mm (8″ – 160″)

Wall Thickness: 3.2 mm – 40mm

Mechanical Properties

| Steel Grade | Yield strength, min. psi (MPa) | Tensil strength, min. psi (MPa) | Elongation in 2 in., min. % |

| GRADE 1 | 30,000 (205) | 50,000 (345) | 30% |

| GRADE 2 | 35,000 (240) | 60,000 (415) | 25% |

| GRADE 3 | 45,000 (310) | 66,000 (455) | 20% |

Anti-Corrosion Coating

Specifications:

Single layer fusion bonded epoxy (FBE) external coating

Two layer fusion bonded epoxy (2FBE) external coating

Two or three layer polythene (2PE/3PE) external coating

Two or three polypropylene (2PP/3PP) external coating

Liquid epoxy or internal anti-corrosion coating

CAR-Lined Compound Steel pipe

Concrete Weight Coating (CWC) for pipe seabed