BLRF Flange,Blind flange

Blind flange is a kind of round plate with no center hole but with all the proper bolt holes. It is used to blank off the ends of piping, valves and pressure vessel opening. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed of all flange types; however, since the maximum stresses in a blind flange are bending stresses at the center, they can safely be permitted to be higher than in other types of flanges.

Materials used:Some materials used in the manufacturing of blind flanges are as follows:

- Stainless Steel

- Nickel Alloy

- Titanium

- Carbon Steel

- Cast Iron

- Brass

- Bronze

- Steel

- Aluminum

- Polypropylene

- Silicone

- Features of blind flanges:Some important features of blind flanges are as follows:

BLRF Flange,Blind flange

Blind Flange

They may often be supplied with NPT fittings to allow pressure test connections to be fitted.

These Flanges are available in the following range.

Features of blind flanges:Some important features of blind flanges are as follows:

|

They may often be supplied with NPT fittings to allow pressure test connections to be fitted.

These Flanges are available in the following range.

Stainless Steel: ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F310, F310S, F321, F321H, F317, F347, F347H, F904L.

Duplex Stainless Steel: UNS S31803, UNS S32750

Carbon Steel: ASTM A105,

Alloy Steel: ASTM A182 F1, F11, F22, F5, F9, F91

Nickel Alloys: Monel 400 & 500, Inconel 600 & 625, Incoloy 800, 825, Hastelloy C22, C276

Copper Alloys: Copper, Brass & Gunmetal

Size: 1/8" NB TO 48"NB.

Sch: 5s, 10s, 10, 20, 40s, 40, STD, 60, 80s, 80, XS, 100, 120, 140, 160, XXS

Class: 150#, 300#, 400#, 600#, 900#, 1500#, 2500#

Dimensional Standard

ANSI: ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638, DIN 2673

B.S: BS 4504, BS4504, BS1560, BS10

Duplex Stainless Steel: UNS S31803, UNS S32750

Carbon Steel: ASTM A105,

Alloy Steel: ASTM A182 F1, F11, F22, F5, F9, F91

Nickel Alloys: Monel 400 & 500, Inconel 600 & 625, Incoloy 800, 825, Hastelloy C22, C276

Copper Alloys: Copper, Brass & Gunmetal

Size: 1/8" NB TO 48"NB.

Sch: 5s, 10s, 10, 20, 40s, 40, STD, 60, 80s, 80, XS, 100, 120, 140, 160, XXS

Class: 150#, 300#, 400#, 600#, 900#, 1500#, 2500#

Dimensional Standard

ANSI: ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638, DIN 2673

B.S: BS 4504, BS4504, BS1560, BS10

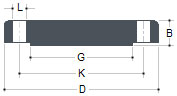

| DIMENSIONS of CLASS 150 FLANGES AS PER ANSI B 16.5 | |||||||

| NB | D | B | G | K | L | No. of Holes | |

| ½” | 15 | 88.9 | 11.1 | 34.9 | 60.3 | 15.9 | 4 |

| ¾” | 20 | 98.4 | 12.7 | 42.9 | 69.8 | 15.9 | 4 |

| 1” | 25 | 107.9 | 14.3 | 50.8 | 79.4 | 15.9 | 4 |

| 1 ¼” | 32 | 117.5 | 15.9 | 63.5 | 88.9 | 15.9 | 4 |

| 1 ½” | 40 | 127.0 | 17.5 | 73.0 | 98.4 | 15.9 | 4 |

| 2” | 50 | 152.4 | 19.0 | 92.1 | 120.6 | 19.0 | 4 |

| 2 ½” | 65 | 177.8 | 22.2 | 104.8 | 139.7 | 19.0 | 4 |

| 3” | 80 | 190.5 | 23.8 | 127.0 | 152.4 | 19.0 | 4 |

| 4” | 100 | 230.0 | 23.8 | 157.2 | 190.5 | 19.0 | 8 |

| 5” | 125 | 254.0 | 23.8 | 185.7 | 215.9 | 22.2 | 8 |

| 6” | 150 | 279.4 | 25.4 | 215.9 | 241.3 | 22.2 | 8 |

| 8” | 200 | 342.9 | 28.6 | 269.9 | 298.4 | 22.2 | 8 |

| 10” | 250 | 406.4 | 30.2 | 323.8 | 361.9 | 25.4 | 12 |

| 12” | 300 | 482.6 | 31.8 | 381.0 | 431.8 | 25.4 | 12 |

| 14” | 350 | 533.4 | 34.9 | 412.7 | 476.2 | 28.6 | 12 |

| 16” | 400 | 596.9 | 36.5 | 469.9 | 539.7 | 28.6 | 16 |

| 18” | 450 | 635.0 | 39.7 | 533.4 | 577.8 | 31.7 | 16 |

| 20” | 500 | 698.5 | 42.9 | 584.2 | 635.0 | 31.7 | 20 |

| 24” | 600 | 812.8 | 47.6 | 692.1 | 749.3 | 34.9 | 20 |

| DIMENSIONS of CLASS 300 FLANGES AS PER ANSI B 16.5 | |||||||

| NB | D | B | G | K | L | No. of Holes | |

| ½” | 15 | 95.2 | 14.3 | 34.9 | 66.7 | 15.9 | 4 |

| ¾” | 20 | 117.5 | 15.9 | 42.9 | 82.5 | 19.0 | 4 |

| 1” | 25 | 123.8 | 17.5 | 50.8 | 88.9 | 19.0 | 4 |

| 1 ¼” | 32 | 133.3 | 19.0 | 63.5 | 98.4 | 19.0 | 4 |

| 1 ½” | 40 | 155.6 | 20.6 | 73.0 | 114.3 | 22.2 | 4 |

| 2” | 50 | 165.1 | 22.2 | 92.1 | 127.0 | 19.0 | 8 |

| 2 ½” | 65 | 190.5 | 25.4 | 104.8 | 149.2 | 22.2 | 8 |

| 3” | 80 | 209.5 | 28.6 | 127.0 | 168.3 | 22.2 | 8 |

| 4” | 100 | 254.0 | 31.8 | 157.2 | 200.0 | 22.2 | 8 |

| 5” | 125 | 279.4 | 34.9 | 185.7 | 234.9 | 22.2 | 8 |

| 6” | 150 | 317.5 | 36.5 | 215.9 | 269.9 | 22.2 | 12 |

| 8” | 200 | 381.0 | 41.3 | 269.9 | 330.2 | 25.4 | 12 |

| 10” | 250 | 444.5 | 47.6 | 323.8 | 387.3 | 28.6 | 16 |

| 12” | 300 | 520.7 | 50.8 | 381.0 | 450.8 | 31.7 | 16 |

| 14” | 350 | 584.2 | 54.0 | 412.7 | 514.3 | 31.7 | 20 |

| 16” | 400 | 647.7 | 57.2 | 469.9 | 571.5 | 34.9 | 20 |

| 18” | 450 | 711.2 | 60.3 | 533.4 | 628.5 | 34.9 | 24 |

| 20” | 500 | 774.7 | 63.5 | 584.2 | 685.8 | 34.9 | 24 |

| 24” | 600 | 914.4 | 69.8 | 692.1 | 812.8 | 41.3 | 24 |

| DIMENSIONS of CLASS 600 FLANGES AS PER ANSI B 16.5 | |||||||

| NB | D | B | G | K | L | No. of Holes | |

| ½” | 15 | 95.2 | 14.3 | 34.9 | 66.7 | 15.9 | 4 |

| ¾” | 20 | 117.5 | 15.9 | 42.9 | 82.5 | 19.0 | 4 |

| 1” | 25 | 123.8 | 17.5 | 50.8 | 88.9 | 19.0 | 4 |

| 1 ¼” | 32 | 133.3 | 20.6 | 63.5 | 98.4 | 19.0 | 4 |

| 1 ½” | 40 | 155.6 | 22.2 | 73.0 | 114.3 | 22.2 | 4 |

| 2” | 50 | 165.1 | 25.4 | 92.1 | 127.0 | 19.0 | 8 |

| 2 ½” | 65 | 190.5 | 28.6 | 104.8 | 149.2 | 22.2 | 8 |

| 3” | 80 | 209.5 | 31.8 | 127.0 | 168.3 | 22.2 | 8 |

| 4” | 100 | 273.0 | 38.1 | 157.2 | 215.9 | 25.4 | 8 |

| 5” | 125 | 330.2 | 44.4 | 185.7 | 266.7 | 28.6 | 8 |

| 6” | 150 | 355.6 | 47.6 | 215.9 | 292.1 | 28.6 | 12 |

| 8” | 200 | 419.1 | 55.6 | 269.9 | 349.2 | 31.7 | 12 |

| 10” | 250 | 508.0 | 63.5 | 323.8 | 431.8 | 34.9 | 16 |

| 12” | 300 | 558.8 | 66.7 | 381.0 | 488.9 | 34.9 | 20 |

| 14” | 350 | 603.2 | 69.9 | 412.7 | 527.0 | 38.1 | 20 |

| 16” | 400 | 685.8 | 75.2 | 469.9 | 603.2 | 41.3 | 20 |

| 18” | 450 | 742.9 | 82.6 | 533.4 | 654.0 | 44.4 | 20 |

| 20” | 500 | 812.8 | 88.9 | 584.2 | 723.9 | 44.4 | 24 |

| 24” | 600 | 939.8 | 101.6 | 692.1 | 838.2 | 50.8 | 24 |

(Tag):BLRF Flange